Minimum order quantity: one container

Price: Starting from $500

payment method: T/T

Supply capacity: 2000m ³/day

Delivery deadline: 7-10 days

Conventional packaging: plastic packaging

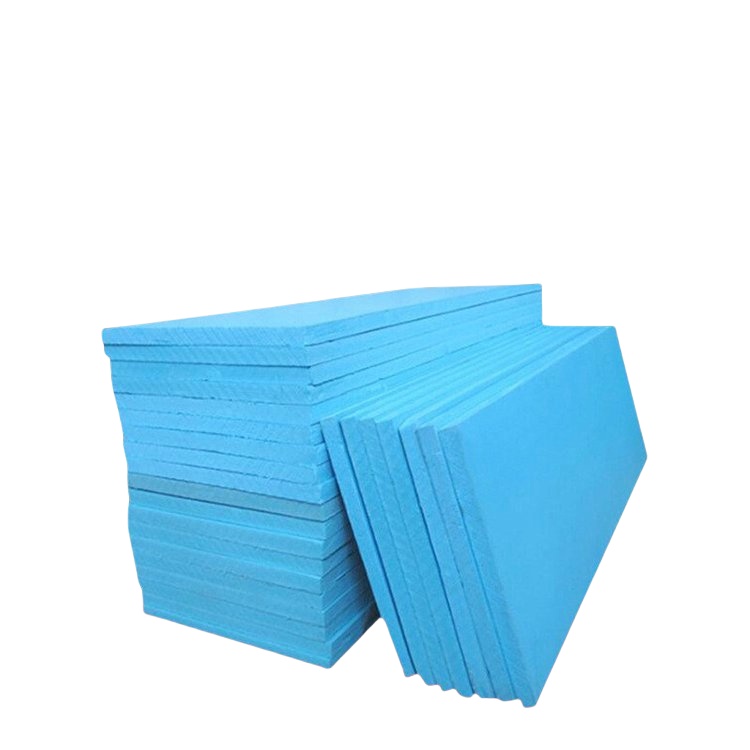

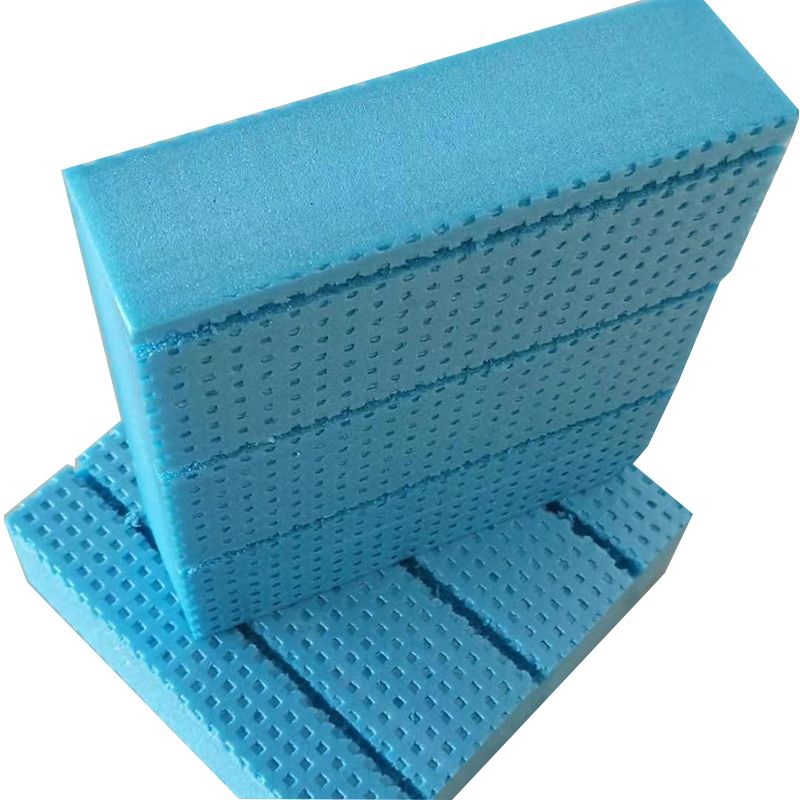

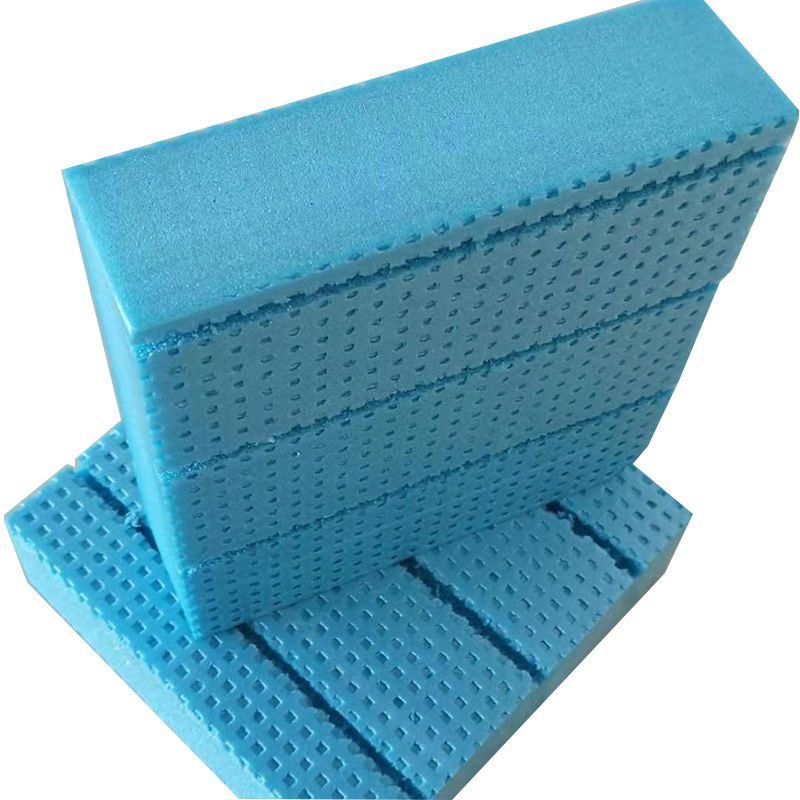

Categories: XPS Extruded Board

1. Widely used for insulation of walls, flat concrete roofs, and steel structure roofs;

2. Used for moisture-proof and thermal insulation in areas such as low-temperature storage floors, parking platforms, airport runways, highways, etc.

Extruded board is a kind of environment-friendly thermal insulation material with high compression resistance, low water absorption, moisture-proof, airtight, light weight, corrosion resistance, super aging resistance (almost no aging after long-term use), and low thermal conductivity.

Extruded polystyrene board is widely used for insulation of dry walls, flat concrete roofs, and steel structure roofs. It is also used for moisture-proof insulation of low-temperature storage floors, low-temperature floor radiant heating pipes, parking platforms, airport runways, highways, and other fields. It controls ground frost heave and is a cost-effective and high-quality insulation and moisture-proof material in the construction industry.

1. Has excellent and long-lasting thermal insulation properties

The goal of all insulation materials is to achieve the lowest possible thermal conductivity. Extruded polystyrene board is mainly made from polystyrene, which is already an excellent low thermal conductivity material. Combined with extrusion extrusion, the tight honeycomb structure effectively prevents heat conduction. The thermal conductivity coefficient of the energy gathering board is 0.028W/m · k, with high thermal resistance and low linear expansion rate. The thermal conductivity is much lower than other insulation materials. Such as EPS board, foamed polyurethane, insulation mortar, perlite, etc.

2. Superior water resistance and moisture resistance

Extruded polystyrene board has a tight closed cell structure, and the molecular structure of polystyrene itself does not absorb water. There are no gaps on both sides of the board, so the water absorption rate is extremely low, and the moisture and penetration resistance are excellent.

3. Corrosion resistance and durability

Ordinary hard foam insulation materials are prone to aging after several years of use, leading to a decrease in water absorption and performance. However, extruded polystyrene board has excellent anti-corrosion, anti-aging, insulation properties, and can maintain its excellent performance even under high water vapor pressure, with a service life of up to 30-40 years.

According to the compressive strength p and skin of the product, it can be divided into the following ten categories:

a. X150-p greater than 150 kPa, with epidermis;

b. X200-p greater than 200 kPa, with epidermis;

c. X250-p greater than 250 kPa, with epidermis;

d. X300-p greater than 300 kPa, with epidermis;

e. X350-p greater than 350 kPa, with epidermis;

f. X400-p greater than 400 kPa, with epidermis;

g. X450-p greater than 450 kPa, with epidermis;

h. X500-p greater than 500 kPa, with epidermis;

0-200-p greater than 200 kPa, without skin;

j. W300-p greater than 300 kPa, without skin.

Products with other surface structures shall be agreed upon by both the supply and demand parties

According to the edge structure of the product, it can be divided into the following four types:

1. SS flat head product

2. Si type product (overlap)

3. TG type product (birch groove)

4. RC type product (rain trough)

XPS national standard of extruded polystyrene foam for thermal insulation GB/T10801.2-2002

Thermal performance density 32.00Kg/m ³, thermal conductivity 0.028W/(m.K), thermal storage coefficient 0.40W/(㎡. K), correction factor α

Code for Thermal Design of Civil Buildings GB 50176-2006 Appendix B Thermal Calculation Parameters Extruded Polystyrene Foam Dry Density 350Kg/m ³

Thermal conductivity coefficient 0.030W/(m.K) (with skin) 0.032W/(m.K) (without skin) Thermal storage coefficient 0.34W/(㎡. K)

Luya focuses on creating high-quality, environmentally friendly and energy-saving products with professional production technology, rigorous management, advanced equipment, and unremitting efforts to pursue sustained and extensive brand influence in the global new building materials field.

In terms of after-sales service, the company has a high-quality marketing and construction team, a sound service network, and stable and smooth raw material supply channels. At present, our leading products are distributed throughout the country and have been exported to more than ten countries and regions including Russia, Indonesia, Myanmar, Vietnam, Tajikistan, Iraq, etc.

Copyright © 2025 Luya Insulation Materials Hebei Co., Ltd. | Privacy Policy