Minimum order quantity: one container

Price: Starting at $500

payment method: T/T

Supply capacity: 1000 tons/day

Delivery deadline: 7-10 days

Conventional packaging: Plastic packaging (different specifications and sizes, please consult for details)

Categories: Rock Wool

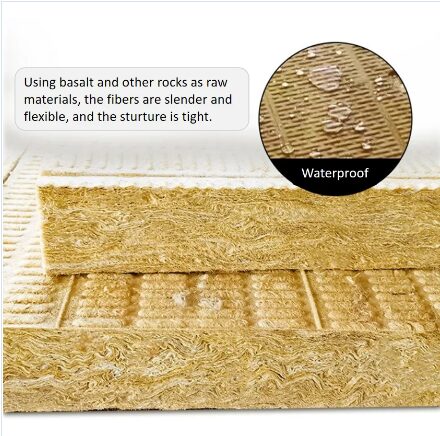

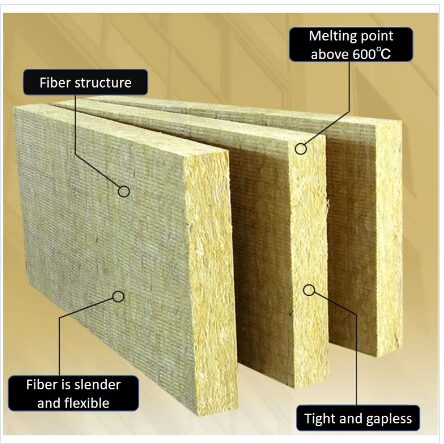

Rock wool is mainly made from natural rock, melted at high temperature, and then made into artificial inorganic fibers by high-speed centrifugal equipment. At the same time, special binders and dust-proof oil are added, and then heated and solidified to produce various specifications and requirements of rock wool insulation products. Rock wool and mineral wool can be made into rock wool board, rock wool strip, rock wool felt, rock wool blanket (rock wool felt), rock wool pipe and other rock wool products.

Rock wool board can be divided into fire-resistant rock wool board, waterproof rock wool board, aluminum foil coated rock wool board, and other types.

Stone wool board, also known as rock wool insulation decorative board, is an inorganic fiber board made from basalt as the main raw material and processed by high-temperature melting. It was successfully tested in June 1981 and is a new type of insulation, flame-retardant, and sound-absorbing material.

Elastic, medium strength rock wool board: suitable for building wall/roof insulation, fire prevention, sound absorption, such as curtain walls, interior wall partitions, elevator shafts, etc.

High strength rock wool board: suitable for various conditions of high and low temperature, with good load-bearing and compressive properties, especially suitable for insulation and thermal insulation of large ships, containers, ovens, pipelines, and industrial equipment.

Pressure resistant rock wool board: capable of withstanding huge high loads. Suitable for roof insulation in waiting rooms, large workshops, etc

Firstly, the staff should polish the board joints in a timely manner, and the polishing time should be carried out after the foam adhesive has formed a solid state. This is the most basic maintenance of rock wool. If the board joints are polished immediately after using the foam adhesive, it will easily affect the performance of the rock wool, so special attention must be paid;

Secondly, during the normal use of rock wool products, we should promptly clean the stains on the surface of the rock wool, with a short cleaning cycle to ensure that there are no accumulated stains on the surface of the rock wool.

Thirdly, under low temperature conditions, the surface of rock wool will become more brittle, so we need to avoid sharp objects hitting the rock wool to avoid damage.

Fourthly, relevant personnel should have a thorough understanding of the characteristics of rock wool products, and make detailed records of any precautions during the construction process to avoid accidents. In addition, personnel should always pay attention to weather changes. If encountering rainy or snowy weather, construction should be stopped in advance and must not be carried out in adverse weather conditions.

Luya focuses on creating high-quality, environmentally friendly and energy-saving products with professional production technology, rigorous management, advanced equipment, and unremitting efforts to pursue sustained and extensive brand influence in the global new building materials field.

In terms of after-sales service, the company has a high-quality marketing and construction team, a sound service network, and stable and smooth raw material supply channels. At present, our leading products are distributed throughout the country and have been exported to more than ten countries and regions including Russia, Indonesia, Myanmar, Vietnam, Tajikistan, Iraq, etc.

Copyright © 2025 Luya Insulation Materials Hebei Co., Ltd. | Privacy Policy